The Evolution / Revolution of Overhead Conductors... and why it matters

Brief Background:

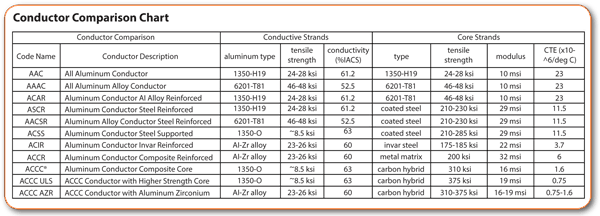

In the early 1900’s Aluminum Conductor Steel Reinforced (ACSR) conductor was developed to replace copper wires, due to the war effort when copper was needed for munitions. In the 1970’s growing demand for electricity inspired the development of higher capacity Aluminum Conductor Steel Reinforced (ACSS) conductor. The ACSS conductor became known as the first “High-Temperature, Low-Sag” (HTLS) conductor. The design used the same steel core as ACSR (with improved galvanized coatings) and fully annealed aluminum so it could operate at higher temperatures and allow the delivery of more electric energy. While fully annealed aluminum is slightly more conductive than non-annealed aluminum, it is somewhat weaker, so overall conductor strength was slightly decreased. In the 1990’s a number of conductor manufacturers began using higher strength steel to make up the difference. Comparative data can be found in the chart below.

Something New:

In the early 2000’s, a handful of manufacturers introduced composite core conductors such as Aluminum Conductor Composite Reinforced (ACCR)1 and Aluminum Conductor Composite Core (ACCC)2. The ACCR conductor replaced the steel core wires with aluminum wires reinforced with ceramic fibers. The improved conductivity of the core compared to steel and ability to operate at higher temperatures due to the utilization of anneal-resistant aluminum-zirconium alloy, enabled the ACCR conductor to carry twice the twice the current of ACSR conductors, with decreased thermal sag.

While ACSS conductors (and other HTLS conductors shown in the adjacent sag graph) can also carry twice the current of ACSR conductors, the coefficient of thermal expansion of various conductor cores differs and, in some cases, could cause the conductor to sag below safe clearances at higher temperatures depending upon structure height, initial tension and so forth.

Data provided in the Sag Comparison chart was compiled by Hydro One during testing at Kinectrics Lab in Toronto, Ontario, Canada. A Drake size ACSR conductor was installed on a 215 foot test span inside the lab. Each of the “novel” conductors were subsequently installed at equal tension, and a 1,600 amp load was applied (in series) to compare conductor sag.

While the ACSR conductor was only designed to operate at ~75° C, due to the fact that the aluminum will begin to anneal at 93° C, the other conductors depicted in the graph were designed to operate at higher temperatures without degradation or weakening due to annealing.

One of the most interesting aspects about this comparison of HTLS conductors is the fact that the ACCC Conductor carried equal current at substantially cooler temperatures compared to the other conductors tested.

ACCC® Conductor Design:

The ACCC® Conductor replaced the steel core (or aluminum core strands) with a single non-conductive carbon and glass fiber composite core. This design, coupled with the use of compact trapezoidal aluminum strands, allows a 2X increase in capacity with greatly reduced thermal sag. The standard ACCC Core has a coefficient of thermal expansion of 1.6 x 10-6 per degree C, which is about ten times less than steel (11.5 x 10-6 per degree C), and nearly twenty times less than aluminum (23.0 x 10-6 per degree C). The ACCC Conductor is also available in a higher strength - higher modulus (“ULS”) version that further reduces the coefficient of thermal expansion to 0.75 x 10-6 per degree C. The ULS version also increases tensile strength from 310 ksi to 375 ksi. For comparison, high strength steel is generally rated at 285 ksi.

While the ACCC Composite core is fully elastic and will not plastically (and permanently) deform like steel or aluminum when subjected to severe wind or ice loads, it can exhibit greater ice load sag compared to steel reinforced conductors. To combat extreme ice load conditions the base or ULS versions can be used with stronger aluminum-zirconium alloy strands, as shown is the comparison chart.

Read full article in the ELECTRIC UTILITY OPERATIONS Special Edition 2022