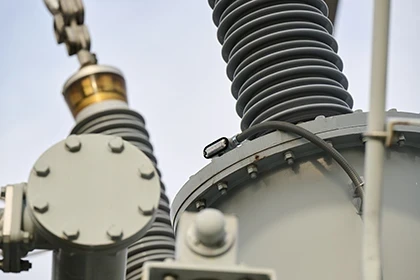

Electrical Transformers

Transformers and the Power Grid

POWER TRANSFORMERS. Surplec Repair Facilities

Electrical Transformers

Purchasing Reconditioned Electrical Equipment

Debunking the myths about tested and refurbished equipment

BY RISHI SUDAN, RS Electrical Supply

Extending the lifecycle of capital equipment such as 15-kilovolt circuit breakers, switchgear, and transformers through testing and reconditioning saves time and money by cutting down on new equipment purchases and eliminating associated downtime with major equipment replacement. However, many utilities doubt the reliability of reconditioned electrical equipment for a number of reasons. Many utilities believe that reconditioned equipment is not as...

Related Articles

POWER TRANSFORMERS. Surplec Repair Facilities

Repairing & Remanufacturing your transformer offers a solution that is both technically and economically efficient. Through repairs, we restore a transformer to its original condition in all aspects (current, voltage and impedance). Remanufacturing, on the other hand, involves, e.g., providing...

Grounding Transformers Explained

By R. W. Hurst, Editor Grounding transformers are used to provide a path to ground for unbalanced load current and for fault currents on systems where a suitable ground is otherwise not available. Grounding transformers are normally constructed with one of the two configurations: Zig-Zag (Zn) with...

The Distribution Transformer - Critical Power System Component

By R.W. Hurst, Editor A distribution transformer is a critical component of the electrical power system, used to reduce the voltage of electrical energy for electric power distribution to end-users. It plays a vital role in voltage regulation and load management, ensuring the efficient and reliable...

Renewable Insulation Liquids for Transformers

Turning electrical assets into green machines BY RONNY FRITSCHE & GEORG PUKEL, Siemens AG Transformers are one of the most important components of energy grid systems. They enable the efficient transport of electric energy from the location where the energy is generated to the location where...

The Role of Transformer Oil Alternatives in Improving Safety and Environmental Sustainability

The Growing Need for Safer and Greener Transformer Oils Transformer oil plays a vital role in the operation and longevity of power transformers, providing insulation, cooling, and arc suppression. Traditionally, mineral oil has been the industry standard due to its effective dielectric properties...

Enhancing Transformer Resilience: Fire Barriers and Safety Measures in Modern Substations

The Growing Concern of Transformer Fire Risks An Electrical Substation Transformer is a critical component of modern substations, playing a vital role in the transmission and distribution of electricity. However, due to the high-voltage operations, flammable insulation materials, and exposure...

Navigating the Transformer Supply Crunch: Strategies for Utilities Amidst Global Shortages

The Growing Transformer Supply Crisis The global transformer supply chain is facing unprecedented challenges, with utilities worldwide struggling to procure essential equipment due to material shortages, manufacturing delays, and logistical constraints. Transformers are the backbone of electrical...

MITIGATING TRANSFORMER FAILURES: ADVANCED MONITORING AND MAINTENANCE STRATEGIES

Power transformers are critical assets in electrical transmission and distribution networks. Their failure can lead to widespread outages, costly downtime, and potential safety hazards. As transformers age and operate under varying electrical and environmental stresses, degradation becomes...

Transmission Construction Industry Leader Retires and Sells at Absolute Auction!

S.E., Inc. has been providing the very best in Transmission Powerline Construction for over (40) years throughout the Western United States. Brothers Mark, Steve, David, and Craig Sorenson have decided to retire and pursue other interests. Everything in the auction is owned by S.E., Inc. and will...

Understanding Bushing Failure Modes and Monitoring for Optimal Transformer Health

Monitoring the health of bushings is vital for ensuring the reliability of transformers, especially in high-stakes environments like power grids and industrial facilities. Bushings, critical components of transformers, are prone to various failure modes that can lead to operational inefficiencies...