Transformer Testing & Maintenance

New FLIR T860 High-Performance Thermal Camera Streamlines Industrial Inspections

Advancements in Dissolved Gas Analysis: Investigating Failure Cases

Transformer Testing & Maintenance

How to Improve Transformer Protection

Using symmetrical components for fault discrimination in differential protection

BY IMRAN RIZVI, ABB Inc.

Classical differential protection schemes are subject to ghost differential currents due to current transformer (CT) saturation and magnetization currents. Several methods are used to counter the impact of these unwanted differential currents. Electricity Today Magazine and ABB will focus on how to improve transformer protection by using the symmetrical component techniques to stabilize differential protection schemes without sacrificing the speed and...

Related Articles

Advancements in Dissolved Gas Analysis: Investigating Failure Cases

IntroductionDissolved gas analysis (DGA) provides the early warning radar view of a transformer fleet with a non-intrusive screening process for early identification of problematic transformers. Suspicious transformers can be subjected to more invasive and costly physical testing to determine the...

Advancements in Dissolved Gas Analysis: NEI & Gassing Events

One of the most important steps when looking at DGA data is to decide whether the data support the existence of a fault that is actively breaking down the insulation before you try to use a triangle, pentagon, or gas ratio method to identify a fault type. Otherwise, you are diagnosing random...

Insulation Resistance Test

Insulation Resistance (IR) test, often called Megger test, is more than 100 years old and assumed to be a very straightforward test. During my inspection and testing work in the past 15 years in Canada, US, and internationally, I have seen different practices of performing and interpretation of IR...

The Dissolved Gas Analysis Toolkit

Dissolved gas analysis: addressing the challenges of collecting samples BY DONAL SKELLY, GE’s Digital Energy business Dissolved gas analysis (DGA) is a technique for identifying and quantifying the gas formed in oil-filled electrical equipment because of either the natural aging of oil and paper...

The Role of Transformer Oil Alternatives in Improving Safety and Environmental Sustainability

The Growing Need for Safer and Greener Transformer Oils Transformer oil plays a vital role in the operation and longevity of power transformers, providing insulation, cooling, and arc suppression. Traditionally, mineral oil has been the industry standard due to its effective dielectric properties...

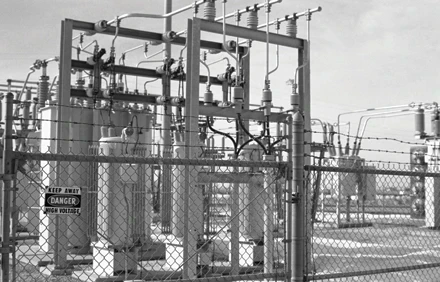

Enhancing Transformer Resilience: Fire Barriers and Safety Measures in Modern Substations

The Growing Concern of Transformer Fire Risks An Electrical Substation Transformer is a critical component of modern substations, playing a vital role in the transmission and distribution of electricity. However, due to the high-voltage operations, flammable insulation materials, and exposure...

Navigating the Transformer Supply Crunch: Strategies for Utilities Amidst Global Shortages

The Growing Transformer Supply Crisis The global transformer supply chain is facing unprecedented challenges, with utilities worldwide struggling to procure essential equipment due to material shortages, manufacturing delays, and logistical constraints. Transformers are the backbone of electrical...

MITIGATING TRANSFORMER FAILURES: ADVANCED MONITORING AND MAINTENANCE STRATEGIES

Power transformers are critical assets in electrical transmission and distribution networks. Their failure can lead to widespread outages, costly downtime, and potential safety hazards. As transformers age and operate under varying electrical and environmental stresses, degradation becomes...

Transmission Construction Industry Leader Retires and Sells at Absolute Auction!

S.E., Inc. has been providing the very best in Transmission Powerline Construction for over (40) years throughout the Western United States. Brothers Mark, Steve, David, and Craig Sorenson have decided to retire and pursue other interests. Everything in the auction is owned by S.E., Inc. and will...

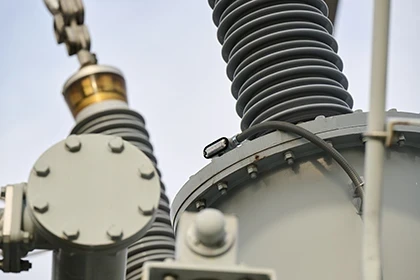

Understanding Bushing Failure Modes and Monitoring for Optimal Transformer Health

Monitoring the health of bushings is vital for ensuring the reliability of transformers, especially in high-stakes environments like power grids and industrial facilities. Bushings, critical components of transformers, are prone to various failure modes that can lead to operational inefficiencies...