The Role of Transformer Oil Alternatives in Improving Safety and Environmental Sustainability

The Growing Need for Safer and Greener Transformer Oils

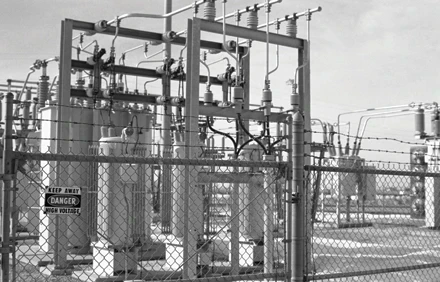

Transformer oil plays a vital role in the operation and longevity of power transformers, providing insulation, cooling, and arc suppression. Traditionally, mineral oil has been the industry standard due to its effective dielectric properties...