DTM Bushing Health Monitor

\n \n

The DTM Bushing Health Monitor detects problems to prevent failure of transformer bushings, windings, and the bus connected to the transformer.

\nThe DTM Monitor configuration, historical data and detailed diagnostics provides an indication of the location, type and rate at which a problem is developing so that you can plan accordingly.

\n\n\t\t

Bushing Health Monitor Module (BHM)

\nContinuous online monitoring of bushings provides real-time information of bushing capacitance and power factor which can result in the early detection of a possible failure. DTM may be ordered with up to two optional bushing (B) modules.

\nThe bushing module collects top oil temperature, load current and humidity inputs

\nto provide a correlation with the bushing condition. This allows the system to reveal whether there is a specific inception point where the equipment deterioration accelerates.

The bushing module provides a discrete reading for each bushing. The reference is

\nrotated to each of the three bushings providing the same high quality of reading on each bushing.

Partial Discharge Monitor Module

\nThe partial discharge module measures electrical partial discharges (PD) in the transformer, bushing, and when applicable, the connected Iso-Phase Bus. The DTM may be ordered with up to two optional (E) modules.

\nElectrical PD monitoring is the perfect second level diagnostic tool to complement DGA and bushing monitoring systems. While a DGA system can indicate the type of fault, the electrical PD system can identify electrically where a fault is in the tank (identifying the phase and the winding).

\n\n\t\t

Advanced Analytics

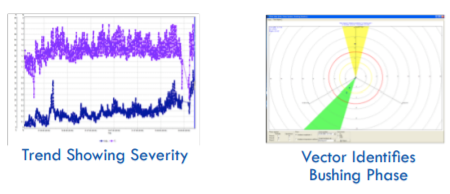

\nThe key analytic for bushing monitoring is the magnitude and trend of the current imbalance. A DTM can provide system alarms on both of these quantities. Secondary analytics include behavior of the current imbalance with top oil temperature and the vector of the current imbalance. The magnitude of the current imbalance will provide information as to how severe the problem is. The vector will provide the indication of which bushing is failing and will identify if the power factor or capacitance of the bushing is changing.

\n\n\t\tGeneral Info

\n\n\t\tWhat’s the Difference Between Sum of Currents and Voltage Reference?

\n\n\t\tPublications

\n\n\t\t\xc2\xa0INMR Article: Unusual Bushing Failure Modes Detected with Online Monitoring

\n\n\t\t\xc2\xa0Transformer Magazine Article: Bushing Sensors and their Role in Bushing Monitoring

\n\n\t\t\xc2\xa0Transformer Magazine Article: Are Through Faults & Slow Breakers Damaging Your Transformers?

\n\n\t\tWhite Papers

\n\n\t\t\xc2\xa0Online Bushing Monitoring Compared to Offline Testing

\n\n\t\t\xc2\xa0How to Obtain the Secrets Your Transformer is Keeping

\n\n\t\t\xc2\xa0Review of Online PD Measurements

\n\n\t\t\xc2\xa0Measurement Methodologies for Maximizing the Reliability of HV Electrical Equipment

\n\n\t\t\xc2\xa0Offline Bushing Tests May Not Confirm Alarms from Online Monitoring

\n\n\t\tNew Release Information

\n\n\t\tUser Resources

\n\n\t\tCase Studies

\n\n\t\tSupport Requests

\nIf immediate response is required, please directly contact your local Dynamic Ratings location:

\nAsia Pacific

\n+61 3 8544-0700

\n[email protected]

Americas

\n+1 262 746 1230 x3

\n[email protected]

Europe/Africa

\n+44 1617 681111

\n[email protected]

\n

Check out our\xc2\xa0Youtube Page\xc2\xa0for instructional tutorials or our\xc2\xa0Customer Portal\xc2\xa0for software and manuals (login required).

\nFor all other requests, please fill out the contact form below:

\n\n\t\tFind out more about how Dynamic Rating’s LIFESTREAM\xc2\xae Support Services ensure successful monitoring through lifecycle support.

\n\n\n\t\t