5 Ways to Improve Bucket-to-Ground Communication

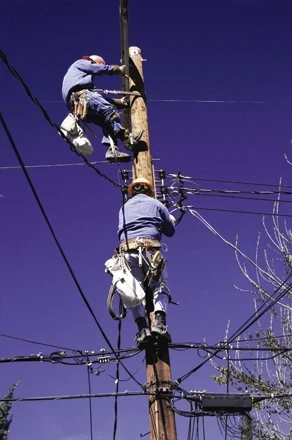

Cranes, aerials and bucket trucks are common sights in construction zones and among maintenance crews around our cities. What better way to hoist materials to high places or to move workers closer to the task?

When your crew includes an above-ground operator in a bucket or cab, they’re linked to ground activity via a dedicated spotter. A spotter’s job is to free up the operator to focus on what they’re doing, uninterrupted from jobsite distractions. Here are five ways to improve communication between these two.

1. KEEP COMMANDS SIMPLE

The fewer commands being used, the better. Whether it’s OSHA’s standard method of hand signals

or variations that your crew has put into practice, make sure visual signs and verbal cues are distinct from each other to avoid confusion. And decide – in advance – which ones you’ll be using.

Visual vs. verbal – the type of work and equipment you need to manage should dictate your mode of communication. A tower crane operator won’t always have their bellman in sight, but a cement truck travelling 20 feet in reverse is well within visual and voice range of a spotter, using mirrors and with windows rolled down.

Verbal is always the go-to choice when there’s more complex detail with work instructions. Communication devices work well on most job sites. Those that offer multi-channel options allow for dedicated, private communication with the ability to include others, if you choose.