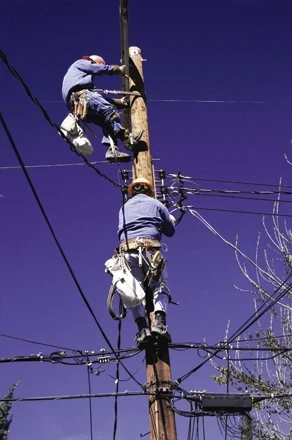

The Right Vendor Partnerships Positively Impact Line Crew Safety

A variety of factors influence the safety of those who work on utility lines. Many of the items are standard and likely on everyone’s line worker safety checklist. But there’s one that may not be top-of-mind when considering how to keep linemen and linewomen safe — the influence technology vendors can have on worker safety.

Some of the more typical elements of a safe work environment for utility line crews include adherence to the National Electrical Safety Code (NESC), training programs and personal protective equipment (PPE). But the less common safety element we want to highlight relates to innovative technology provided by customer-centric vendors.

Investment in the Right Technology From the Right Vendors

State-of-the-art solutions like those having to do with intelligent grid sensors, collection of data and predictive analytics can position a utility company to meet and exceed industry safety and reliability standards. Most importantly, these solutions provide crews with the best available technology and information, helping to protect each line worker’s safety, health and life.

How does innovative technology like Sentient Energy’s Grid Analytics System positively impact line crew safety? Smart technology can significantly reduce higher safety-risk scenarios for line workers in a number of ways, including:

Intelligent line sensors add another layer of safety checks, detecting lines still being energized when they are supposed to be off.

These same sensors also serve as a crew safety tool, used to identify conditions when back-feeding may exist on an assumed dead conductor.

Line sensors measure fault currents at the affected section rather than at the substation, allowing the DMS to provide crews with much more precise fault location information. This substantially reduces patrolling and crew interaction with the grid in suspected but not faulted locations — lowering both travel and line testing risks.