An Overview of Substation Maintenance: Its Evolution and Key Testing Practices

As electrical systems age, operating costs increase while reliability dwindles. Given most utilities and industrial facilities are highly capital intensive and have limited financial and other resources to make wholesale equipment replacements, regular maintenance is critical for controlling the symptoms of aging.

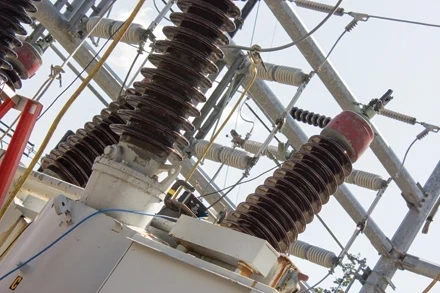

Maintenance is a key part of lifecycle asset management. Preserving equipment health maximizes the efficiency and cost-effectiveness of substation assets, including transformers, circuit breakers, protection equipment, CTs, PTs, CCVTs, batteries, transmission lines, and more. Effective maintenance also helps minimize lifecycle and insurance-related costs, accidents, and environmental compliance issues, reduce the risk of unplanned shutdowns and negative publicity, and ultimately extend the life of an asset.

The Evolution of Maintenance Practices

Utilities have long relied on three types of maintenance techniques: letting assets run until they fail, maintaining assets only when absolutely necessary, or implementing a fixed maintenance schedule. But these approaches alone don’t provide the level of protection necessary to extend the lifecycle of today’s substations.

Today, the best maintenance approaches combine two or three of the following strategies:

- Time-based maintenance (TBM): Involves testing at specific intervals.

- Condition-based maintenance (CBM): The amount and interval of maintenance performed are based on the condition of the asset.

- Performance-based maintenance (PBM): Extends TBM test time intervals by analyzing records showing low failure rates of particular equipment families receiving TBM. This approach is also often referred to as reliability-centred maintenance (RCM).

Due to tremendous advances in online and offline diagnostics, CBM has taken hold over the years. Online dissolved gas analysis, sweep frequency response analysis, automated tracking of faults, analysis of online winding temperature, and monitoring of moisture within the insulation all provide the information needed to perform CBM and can result in significant savings compared to time-based maintenance strategies.

The benefit of CBM is that when conducted properly, the approach enables utilities to identify and fix issues as soon as they fail, without having to deal with lengthy and costly downtime. Teams also don’t have to worry about the risk of damage or human error and can free up employees’ time for critical initiatives like asset replacement and problem-solving.

You can also visit our Substation Maintenance Training course.

Visit our Electricity Forum Electrical Substation Channel Page.

Read full article in the ELECTRIC UTILITY OPERATIONS Special Edition 2022