Bringing Science to Transformer Risk Management

Reliability-based Dissolved Gas Analysis is a new methodology that provides the most correct interpretation of dissolved gas analysis available today.

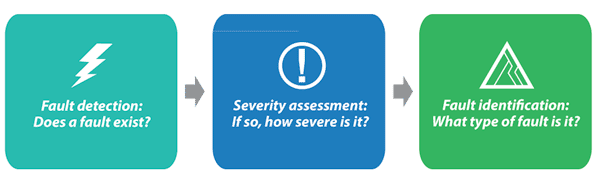

All DGA testing is intended to identify transformers with heat-generating faults that break down the transformer’s internal insulation systems -- the insulating oil and the paper. It can be described as a 3-step process:

Conventional DGA uses a limits-based approach that does not reliably address fault detection or severity assessment, limiting the usefulness of the results and creating challenges for users.

Reliability-based DGA is based on a statistical model built using real-world transformer fault gas and failure data. It offers a much more comprehensive interpretation of DGA results than conventional DGA.

A fault energy index can be calculated to show the heat energy expended by a fault to convert the insulating oil and paper into the observed combination of fault gases.

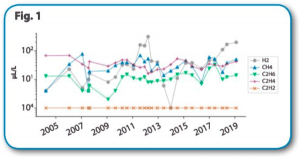

Interpreting an array of fault gas data is complicated, particularly for marginal cases often undetected by conventional DGA. Fault energy indices are a simpler, more practical way of detecting and assessing incipient faults that generate gases in insulating oil and can more readily detect transformers that are experiencing a fault. For example:

In the fault gas chart (Fig. 1), it would take a trained eye to detect a problem with the transformer. And most computerized systems that simply apply the algorithms and methods offered in IEEE and IEC guidelines will not detect at-risk transformers whose data does not exceed pre-determined thresholds.

However, the application of a fault energy index more readily detects an at-risk transformer – as seen in the chart (Fig. 2). Tracking a fault energy index simplifies the understanding of dissolved gas related faults, accounts for gas loss, and more easily allows partitioning the gassing history into distinct gassing events for more insightful analysis.