Enhance Utlity Fleet Tools & Best Practices

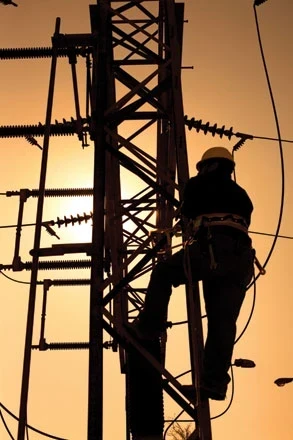

Fleet managers working at electric utilities know that for crews to be successful on any jobsite, they need to have access to tools that will help them work safer, smarter, more efficiently and more profitably. In the electric utility industry, a utility truck, whether an aerial device, such as a bucket truck, a digger derrick, or an auger drill, is critical to a crew’s productivity.

However, as important as the utility trucks are, the work practices in place to protect staff and equipment from the hazards of working around electricity are even more important. Work practices enable fleet managers and their crews to focus on completing jobsite tasks efficiently, effectively and as safely as possible.

The fundamentals of current work practices consider asset management, available equipment offerings, a truck’s technologies, equipment upkeep and maintenance and safety as well as incident prevention. Additionally, fleet managers implement work practices that allow their crews to comply with standards set forth by industry agencies, including the U.S. Occupational Safety and Health Administration (OSHA) and the American National Standards Institute.